The human body: This is generally a schematic based on the overall body—particle/extended, rigid/non-rigid—and on what concerns are to get answered. Thus if rotation of the human body and torque is in thing to consider, an indication of measurement and condition of your body is required.

The air velocity and temperature are critical in this method to make sure the particles present during the product or service bed continue being in a very suspended point out, So acquiring fluidization.

As per the GMP (Superior Production Apply) guidelines, the products Get hold of floor really should be particularly easy. This also can help in avoiding the floor corrosion on account of electrolytic mobile development.

Exploring the prospective of FBDs for novel drug shipping systems and personalized medication programs.

The Fluid bed dryers getting bag filter is hooked up that has a shaking method which helps prevent blockage with the filter. Filters of Fluid bed dryer needs to be inspected prior to use to detect any injury or leakage.

In order to make improvements to operation, efficiency, and reproducibility of a fluidized bed dryer, some parameters need to be controlled. These parameters are categorized into:

This is often realized as the velocity of the recent air is over the terminal settling velocity from the particulate solids. Quite simply, the strain made by draft of scorching fluid (In such a case Hot Air) is ready to not merely equilibrium the weight of (and also gravitation drive exerted by) the soaked mass, and also, is able to lift it upwards against the gravitational force.

It may also make the supplies more appropriate for handling and it can help in appropriate preservation from the components.

Drying is obtained at a constant rate having a home time of about 30 to 40 minutes. Once the drying is accomplished, the fabric is left from the dryer for a while more info to realize ambient area temperature.

FBD has the capacity to take away excess moisture from diverse elements and its Performing principle is so specific and focused on drying the resources devoid of modifying their Bodily characteristics.

This equipment contains a stainless steel chamber by using a removable perforated base; often called a bowl. All the material that should be dried needs to be put in this bowl. How it really works, the air is launched from the bottom of the bowl and heated into a established temperature with the heaters.

This mixture of stable particles and air behave just like a liquid, plus the good is claimed to be fluidized. This process is a lot more effective with the drying of granular solids. In this process Every single granule is surrounded by warm air, so the material is effectively dried.

Granulation abilities have been built-in like fluidized beds granulation, permitting drying and granulation in one unit.

Lets Simplify with approach to understand simple: Loading: The fabric to generally be dried is loaded on to the perforated plate or grid at the bottom in the click here drying chamber. The thickness in the bed is managed to make sure productive fluidization.

Emilio Estevez Then & Now!

Emilio Estevez Then & Now! Kel Mitchell Then & Now!

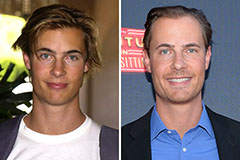

Kel Mitchell Then & Now! Erik von Detten Then & Now!

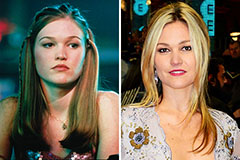

Erik von Detten Then & Now! Julia Stiles Then & Now!

Julia Stiles Then & Now! Tonya Harding Then & Now!

Tonya Harding Then & Now!